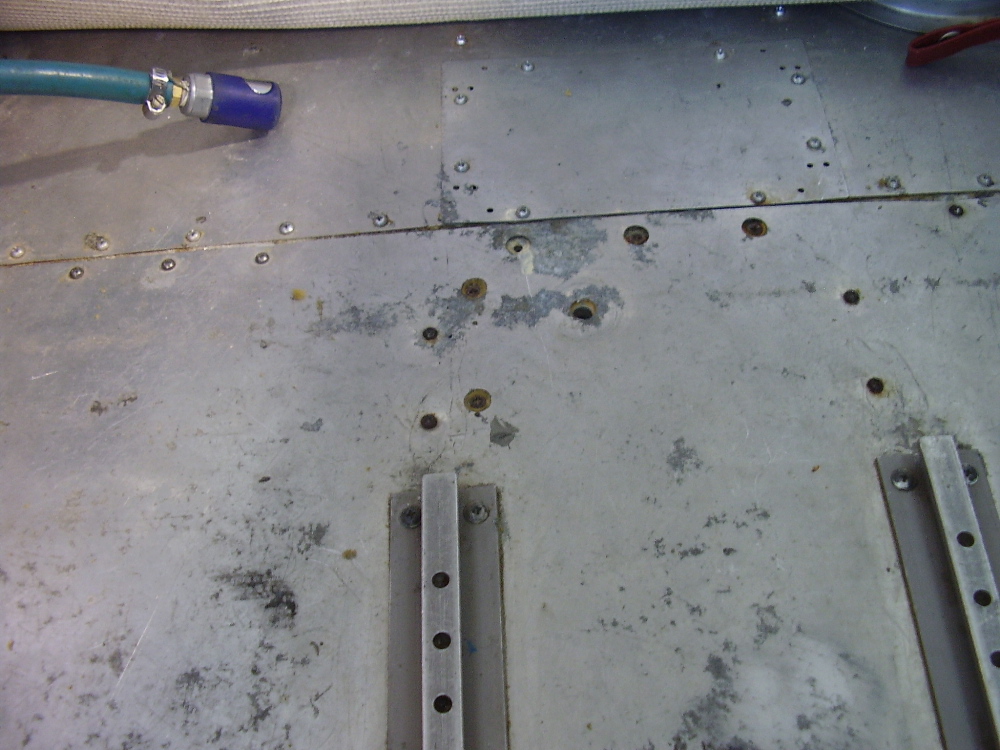

We brought a Baron in for a wing bolt inspection. Normally, the carpets are removed so as to not get them dirty. This revealed corrosion to the baggage floor skin.

There was evidence of past attempts to control the corrosion by sanding. We decided to remove the floor for further inspection. This found bad corrosion to the bottom of the floor, as well as structure in the floor.

Disassembly of the structure started, until all damaged members were removed.

The aft section of the main body skin was also corroded under the soundproofing. Removed structure was cleaned, treated and reassembled.

New belly skin sections fabricated are installed.

New aluminum floor boards were fabricated and installed, aircraft sent out for paint touch up as required.